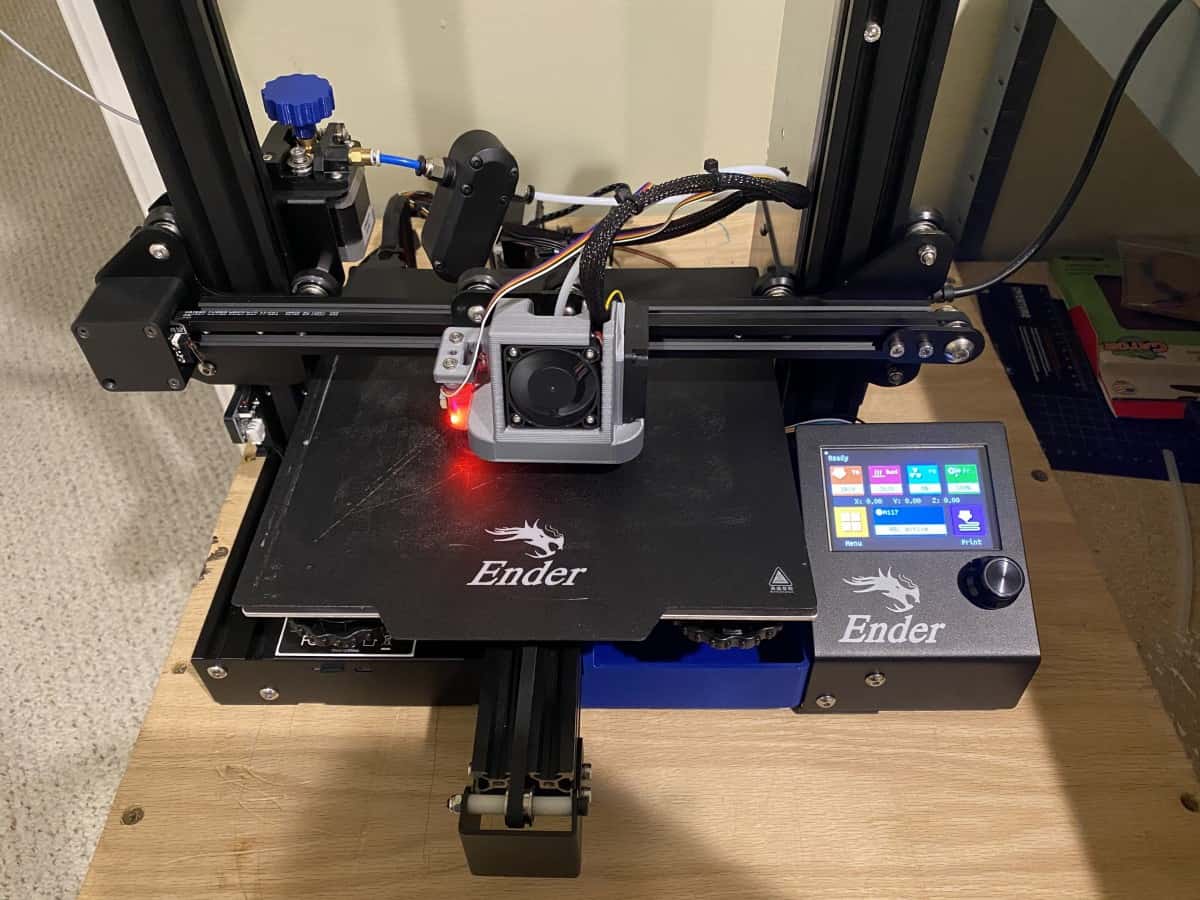

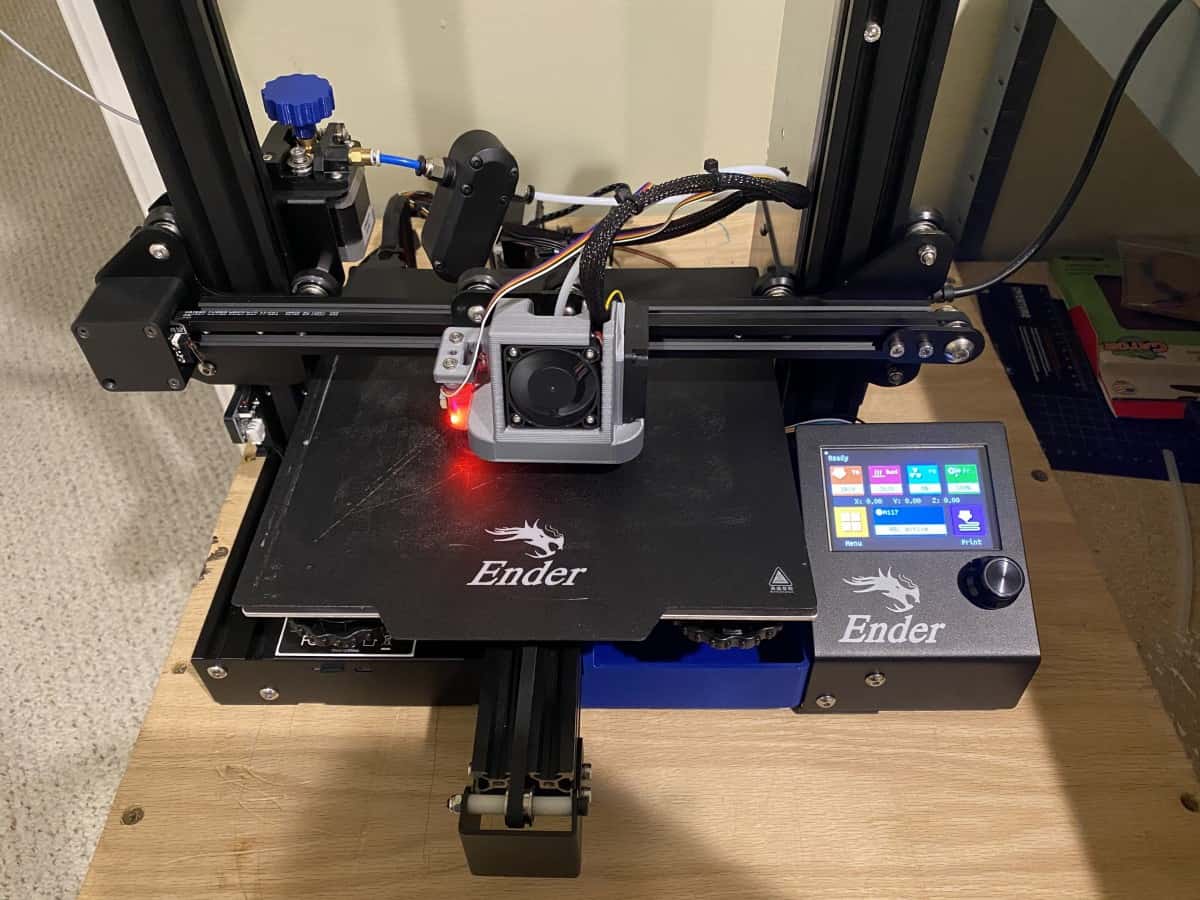

Still, on connectivity, Creality includes both a MicroSD card port and a USB A port for transferring prints. If you feel you need more quality, you can always upgrade it. The stock firmware that comes with the printer offers some basic functionality. The storage compartment can come in handy for storing odds and ends like nozzles, scrapers, etc.įor operating the printer, Creality includes a 3-inch full-color LCD screen with a scroll wheel for navigation. The whole frame is built out of high-strength aluminum extrusions while the power supply is neatly tucked into the base.Īlso, on the base, we have a storage compartment built into the structure. The Ender 3 V2’s design makes it a compact yet elegant addition to any workbench.

Compatible Printing Materials: PLA, TPU, PETG.

The Ender 3 offers premium features and superb print quality at a budget price.Īlso, with its modular nature and open-source firmware, you are sure to have a wonderful time modifying it to suit both your software and hardware needs.

The Creality Ender 3 V2 should be at the top of every newbie’s list.

User Experience of the Artillery Sidewinder X1 V4. Specifications of the Artillery Sidewinder X1 V4. Features of the Artillery Sidewinder X1 V4. User Experience of the Creality CR-10 V3. Specifications of the Creality CR-10 V3. User Experience of the Flashforge Adventurer 3. Specifications of the Flashforge Adventurer 3. Features of the Flashforge Adventurer 3. User Experience of the Anycubic Photon Mono SE. Specifications of the Anycubic Photon Mono SE. Features of the Anycubic Photon Mono SE. So, let’s dive into this list and see how we can transform your virtual models into a physical ones. To help you answer that question, I have prepared a list of some of the best 3D printers for software applications. So, what are the best 3D printers for software applications? But, before we get ahead of ourselves, let’s remember the most important part of this process, the 3D printer. It’s all very exciting stuff, and it’s revolutionizing the way 3D software works. In a matter of hours, these models can be brought to life by a 3D printer. Professionals in all fields like animation, architecture can make 3D prints directly from their software applications without needing a machine shop.įor example, architects can use Revit, animators can use Blender, and even engineers can use Fusion 360 to create designs. Now, as commercial 3D printers become more commonplace, all that is a thing of the past. Before them, you couldn’t create your custom models easily.Īfter designing your 3D files on your software application, you had to take them to a custom machine shop to fabricate them.

One of the advantages of new 3D printers is that they have decentralized manufacturing.

0 kommentar(er)

0 kommentar(er)